Description

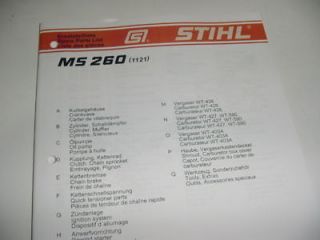

2MS 210, MS 230, MS 250 This service manual contains detailed descriptions of all the repair and servicing procedures specific to this power tool series. As the design concept of model MS 210, 230 and 250 chainsaws is almost identical, the descriptions and servicing procedures in thus manual generally apply to all three models. Find all the parts you need for your Stihl Chainsaw MS 260 at RepairClinic.com. We have manuals, guides and of course parts for common MS 260 problems. Free Stihl Chainsaw parts diagram look up. Jan 08, 2017 Description: Stihl Ms 260 Chainsaw (Ms260 Vw) Parts Diagram, Carburetor Wte 1 with regard to Stihl Ms 260 Parts Diagram, image size 450 X 300 px, and to view image details please click the image. Honestly, we have been noticed that stihl ms 260 parts diagram is being one of the most popular field at this moment.

Stihl 026 Parts List Identification And Repair

Stihl 026 Parts List for the Stihl chainsaw. Repair and service the 026 chainsaw with this manual (IPL), which contains clear repair photos. The manual contains diagrams and accurate information as used by professional mechanics and repair shops to troubleshoot and repair the chainsaw.

View free page images online or download full PDF that you can print or view on any suitable device. The manuals have plenty of pictures and diagrams to make the entire repair process easy for you. Can be used as guides for other models as they may share key components such as motors.

Stihl 026 Parts List Contents

Introduction, Specifications, Troubleshooting Attachments, Clutch, Engine, Ignition, Starter, Servicing, Controls, Fuel System, Special Tools.

The 026 PDF manual contains very detailed diagrams and descriptions. With exploded parts view diagrams you have access to the most comprehensive diagnostic, repair and maintenance information as used by professional mechanics, technicians and repair workshops. The manual is designed to get the information you need quickly and easily.

The Stihl 026 was first produced in 1988 and is still in production today. It changed its name in the 2002 rebranding by the company to Stihl MS 260. It is one of Stihl's professional range of saws. It weighs about the same as a 024 but has a greater displacement so gets the job done quicker. The longest bar recommended for the 026 chainsaws is 20 inches.

Stihl 026 Parts List Manual

Carburetor

Carburetor Adjustment Screws

(LA) Idle Speed screw – This controls the engine speed at idle. If set too low, the saw will die. If set too high the chain will run. This is dangerous.

(L) Low-speed adjustment screw – This is the low-speed jet. This is the adjustment that controls the air/fuel mixture at idle. Adjust this screw too rich and the chainsaw will blubber and die at idle speed. Adjust this screw too lean and the engine will starve. The saw will race or surge. An extremely lean adjustment will also cause the engine to die.

(H) High-speed adjustment screw – This is the high-speed jet. This is the adjustment that controls the air/fuel mixture at high RPMs. Adjust this screw too rich and the chainsaw will blubber, too lean and it will over rev.

Safe Basic Settings

Screws (H) & (L) – Turn the adjustment Screws (H) & (L) down onto their seats (clockwise). Back them off 1 complete turn (counter-clockwise)

Screw (LA) – Turn (LA) Idle Speed screw until the chain stops. Then turn counter-clockwise one-quarter of a turn.

Fine Tuning – Screw (L)

Erratic idling behavior; poor acceleration – Idle setting too lean; turn low-speed adjusting screw (L) counterclockwise until engine runs and accelerates smoothly. Readjust screw (LA).

Exhaust smokes at idle speed –Idle speed setting too rich; turn low-speed adjusting screw (L) clockwise until engine speed drops. Then turn the screw back one-quarter turn and check that engine still accelerates smoothly when you open the throttle. Readjust screw (LA).

Stihl 026 Parts List PDF

Stihl Ms 260 Owners Manual

Robust chainsaw for forestry work

General

Convenient, durable and robust with minimum weight, the STIHL MS 260 can come with a number of optional features to make the job even easier. Recognised as a leading saw in the forestry industry, it is available in guide bar lengths 13'/32cm to 18'/45cm. Can also be used with hedge trimmer attachment HS 246.

Versions

- MS 260, Bar length 40cm, RSC

Deviations from the product range and information provided here are possible, depending on the country. STIHL reserves the right to make changes to technical specifications and equipment.

Technical specifications

Technical specifications

| Technical specifications | Values |

|---|---|

| Displacement | 50,2 cm³ |

| Power output | 2,6/3,5kW/bhp |

| Weight 1) | 4,8 kg |

| Power-to-weight ratio | 1,8 kg/kW |

| Sound pressure level 2) | 99 dB(A) |

| Sound power level 3) | 113 dB(A) |

| Sound power level 3) | 111 dB(A) |

| Vibration level left/right 4) | 3,6/4,1 m/s² |

| Saw chain pitch | .325' |

| STIHL Oilomatic saw chain type | Rapid Super (RS) |

Stihl Ms260 Parts Manual Pdf

1) Without fuel, without bar and chain

2) K-factor according to DIR 2006/42/EC = 2.5 (dB (A))

3) K-factor according to DIR 2006/42/EC = 2.5 dB (A)

4) K-factor according to DIR 2006/42/EC = 2m / s ²

Deviations from the product range and information provided here are possible, depending on the country. STIHL reserves the right to make changes to technical specifications and equipment.

Features

Standard equipment

STIHL ElastoStart

Due to compression pressure, jerky stresses occur when starting internal combustion engines. The damping element in the ElastoStart special starter grip alternately absorbs and releases force according to the compression pattern. The result is smooth, even starting.

Carburettor heating (V)

By changing the chain saw from summer to winter operation, the intake air is pre-heated over the engine fins. This ensures that the carburettor does not ice up and you can continue working in freezing temperatures.

Controlled-delivery oil pump

Different bar lengths, wood types and sawing techniques require different amounts of oil. The controlled-delivery oil pump allows the user to select just the right amount of oil for the job at hand.

Side-mounted chain tensioning

Side-mounted chain tensioning makes it easy to tension the chain safely.

Compensator

This controller in the carburettor prevents the fuel-air mixture getting richer as the air filter becomes clogged. The correct quantity of fuel is delivered to the carburettor depending on the quantity of air passing through the air filter. This keeps the fuel/air ratio in the combustion mixture constant and hence also the engine power. The filter doesn't need to be cleaned until an appreciable drop in power occurs.

Decompression valve

The decompression valve is part of the easy starting system. The valve should be pressed before starting to reduce the compression pressure when starting, as well as reducing the effort needed to pull the starter rope. The decompression valve is semi-automatic; it must be pressed manually before starting, but then closes automatically.

STIHL anti-vibration system

Precisely calculated buffer zones minimise the transfer of engine and saw chain vibrations to the front and rear handles. The chainsaw therefore runs noticeably smoother. This allows the user to save their strength and work longer.

STIHL Ematic System

Compared to conventional bars without Ematic, the STIHL Ematic system reduces the consumption of chain lubricant by up to 50 %, depending on the type of wood and the cutting attachment used. This system comprises a STIHL Ematic or Ematic S guide bar, a STIHL Oilomatic saw chain and a variable-flow or reduced-flow oil pump. As a result, virtually every drop of chain lubricant is delivered to exactly the right spot.

Single-lever master control

All important functions such as start, choke, throttle and stop are operated via a single lever.

Tool free fuel caps

Special caps to open and close the tank cap quickly, easily and without tools.

Retrofitted equipment

Catalytic converter (D)

Considerably reduces the quantity of harmful particles in the exhaust gas.

Introduction, Specifications, Troubleshooting Attachments, Clutch, Engine, Ignition, Starter, Servicing, Controls, Fuel System, Special Tools.

The 026 PDF manual contains very detailed diagrams and descriptions. With exploded parts view diagrams you have access to the most comprehensive diagnostic, repair and maintenance information as used by professional mechanics, technicians and repair workshops. The manual is designed to get the information you need quickly and easily.

The Stihl 026 was first produced in 1988 and is still in production today. It changed its name in the 2002 rebranding by the company to Stihl MS 260. It is one of Stihl's professional range of saws. It weighs about the same as a 024 but has a greater displacement so gets the job done quicker. The longest bar recommended for the 026 chainsaws is 20 inches.

Stihl 026 Parts List Manual

Carburetor

Carburetor Adjustment Screws

(LA) Idle Speed screw – This controls the engine speed at idle. If set too low, the saw will die. If set too high the chain will run. This is dangerous.

(L) Low-speed adjustment screw – This is the low-speed jet. This is the adjustment that controls the air/fuel mixture at idle. Adjust this screw too rich and the chainsaw will blubber and die at idle speed. Adjust this screw too lean and the engine will starve. The saw will race or surge. An extremely lean adjustment will also cause the engine to die.

(H) High-speed adjustment screw – This is the high-speed jet. This is the adjustment that controls the air/fuel mixture at high RPMs. Adjust this screw too rich and the chainsaw will blubber, too lean and it will over rev.

Safe Basic Settings

Screws (H) & (L) – Turn the adjustment Screws (H) & (L) down onto their seats (clockwise). Back them off 1 complete turn (counter-clockwise)

Screw (LA) – Turn (LA) Idle Speed screw until the chain stops. Then turn counter-clockwise one-quarter of a turn.

Fine Tuning – Screw (L)

Erratic idling behavior; poor acceleration – Idle setting too lean; turn low-speed adjusting screw (L) counterclockwise until engine runs and accelerates smoothly. Readjust screw (LA).

Exhaust smokes at idle speed –Idle speed setting too rich; turn low-speed adjusting screw (L) clockwise until engine speed drops. Then turn the screw back one-quarter turn and check that engine still accelerates smoothly when you open the throttle. Readjust screw (LA).

Stihl 026 Parts List PDF

Stihl Ms 260 Owners Manual

Robust chainsaw for forestry work

General

Convenient, durable and robust with minimum weight, the STIHL MS 260 can come with a number of optional features to make the job even easier. Recognised as a leading saw in the forestry industry, it is available in guide bar lengths 13'/32cm to 18'/45cm. Can also be used with hedge trimmer attachment HS 246.

Versions

- MS 260, Bar length 40cm, RSC

Deviations from the product range and information provided here are possible, depending on the country. STIHL reserves the right to make changes to technical specifications and equipment.

Technical specifications

Technical specifications

| Technical specifications | Values |

|---|---|

| Displacement | 50,2 cm³ |

| Power output | 2,6/3,5kW/bhp |

| Weight 1) | 4,8 kg |

| Power-to-weight ratio | 1,8 kg/kW |

| Sound pressure level 2) | 99 dB(A) |

| Sound power level 3) | 113 dB(A) |

| Sound power level 3) | 111 dB(A) |

| Vibration level left/right 4) | 3,6/4,1 m/s² |

| Saw chain pitch | .325' |

| STIHL Oilomatic saw chain type | Rapid Super (RS) |

Stihl Ms260 Parts Manual Pdf

1) Without fuel, without bar and chain

2) K-factor according to DIR 2006/42/EC = 2.5 (dB (A))

3) K-factor according to DIR 2006/42/EC = 2.5 dB (A)

4) K-factor according to DIR 2006/42/EC = 2m / s ²

Deviations from the product range and information provided here are possible, depending on the country. STIHL reserves the right to make changes to technical specifications and equipment.

Features

Standard equipment

STIHL ElastoStart

Due to compression pressure, jerky stresses occur when starting internal combustion engines. The damping element in the ElastoStart special starter grip alternately absorbs and releases force according to the compression pattern. The result is smooth, even starting.

Carburettor heating (V)

By changing the chain saw from summer to winter operation, the intake air is pre-heated over the engine fins. This ensures that the carburettor does not ice up and you can continue working in freezing temperatures.

Controlled-delivery oil pump

Different bar lengths, wood types and sawing techniques require different amounts of oil. The controlled-delivery oil pump allows the user to select just the right amount of oil for the job at hand.

Side-mounted chain tensioning

Side-mounted chain tensioning makes it easy to tension the chain safely.

Compensator

This controller in the carburettor prevents the fuel-air mixture getting richer as the air filter becomes clogged. The correct quantity of fuel is delivered to the carburettor depending on the quantity of air passing through the air filter. This keeps the fuel/air ratio in the combustion mixture constant and hence also the engine power. The filter doesn't need to be cleaned until an appreciable drop in power occurs.

Decompression valve

The decompression valve is part of the easy starting system. The valve should be pressed before starting to reduce the compression pressure when starting, as well as reducing the effort needed to pull the starter rope. The decompression valve is semi-automatic; it must be pressed manually before starting, but then closes automatically.

STIHL anti-vibration system

Precisely calculated buffer zones minimise the transfer of engine and saw chain vibrations to the front and rear handles. The chainsaw therefore runs noticeably smoother. This allows the user to save their strength and work longer.

STIHL Ematic System

Compared to conventional bars without Ematic, the STIHL Ematic system reduces the consumption of chain lubricant by up to 50 %, depending on the type of wood and the cutting attachment used. This system comprises a STIHL Ematic or Ematic S guide bar, a STIHL Oilomatic saw chain and a variable-flow or reduced-flow oil pump. As a result, virtually every drop of chain lubricant is delivered to exactly the right spot.

Single-lever master control

All important functions such as start, choke, throttle and stop are operated via a single lever.

Tool free fuel caps

Special caps to open and close the tank cap quickly, easily and without tools.

Retrofitted equipment

Catalytic converter (D)

Considerably reduces the quantity of harmful particles in the exhaust gas.

Deviations from the product range and information provided here are possible, depending on the country. STIHL reserves the right to make changes to technical specifications and equipment.

Accessories

Accessories

Stihl Chainsaw Parts Ms260

Chainsaw bag

For tidy storage and transport of chainsaws with bar lengths up to 45 cm.

Versions

- Carry bag for chainsaws

Combination socket tool

For tensioning the chain and changing the chain, bar and spark plug. Crack design concept 3d lectra system. Width across flats: 19 (for MS 261 up), 19-13 (for MS 271, MS, 291, MS 311, MS 391), 19–16 (for MS 170, MS 171, MS 180, MS 181, MS 193 C, MS 211, MS 231, MS 241, MS 251), 16 and 13 ( for MS 150, MS 201, MS 201 T).

Versions

- Combination socket tool, width across flats 19-13

Multi-function tool

Practical, multi-function quality tool in a sturdy plastic case. 3.5 mm flat-blade screwdriver for carburettor adjustment and cleaning grooves, Torx® TX 27 screwdriver, nylon pouch with belt loop. Width across flats 19-13 for MS 271, MS 291, MS 311 and MS 391, width across flats 19-16 for MS 170, MS 171, MS 180, MS 181, MS 193 C, MS 211, MS 231, MS 241 and MS 251.

Versions

- Multi function tool, size across flats 19 - 13

Laser 2-in-1

Felling direction indicator and cutting guide in one. For cutting short pieces of wood without complicated measuring, can be used as a felling direction indicator to check the cuts and felling direction, demonstration video on DVD. Choose the holder suitable for your chain saw. Opera browser for mac os x 10.6.8.

Holder 1121 for STIHL Laser 2-in-1

For MS 026, MS 260, all design variants except VW Does armor matter in dark souls.

Versions

- Holder 1121 for STIHL Laser 2-in-1

Deviations from the product range and information provided here are possible, depending on the country. STIHL reserves the right to make changes to technical specifications and equipment.